Standard Optional Features are listed below

See individual options listed below for availability for use with specific valve types.

For modifications available through our Clark Cooper Division, go to the Modifications Page.

Bottom Mounted Options

Manual Override

(Normally Closed valves only)

(Designated by Prefix "MO")

Enables manual opening of solenoid valve during power failure or to override automatic controls.

PUSH BUTTON MANUAL OVERRIDE, see Modifications Page

Dashpot

(Designated by Prefix "DP")

Furnished for clean liquids to reduce water hammer effect sometimes encountered in long pipe runs by slowing valve closing.

Consult factory for valve type availability.

Mounting Stud

(Designated by Prefix "MS")

3/8"-16 thread can be furnished in bottom of body to facilitate mounting on bracket. (Not available on 2", 2-1/2" and 3").

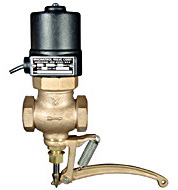

Lever

(Normally Closed valves only)

(Designated by Prefix "LV")

Enables rapid opening of solenoid valve. Can be chain operated for use at inaccessible locations.

Flow Control

(Normally Closed, NR & MR valves, only)

(Designated by Prefix "FC")

Provides a manual method of reducing or throttling the flow.

Drain

(Normally Closed, NR & MR valves, only)

(Designated by Prefix "DR")

1/4" NPT plug supplied in bottom of valve to facilitate draining of liquid from valve body.

Position Indicators

For Normally Closed Solenoid Valves

See the Position Switches page for this option.

*See our Clark Cooper Division for applications requiring:

- Two (2) switches

- Switches on Normally Open Valves

- Switches and a bottom-mounted option

Other Options

Pilot Tap

(Designated by Prefix "PT")

Can be used with any other option. Type D, G & GR Valves can be furnished with 1/8" tapped hole for pilot connection or pressure gauge.

Din Connector

(Designated by Suffix "DN")

Provides 3 prong male connector for easy power connect / disconnect. Female connector provided by others.

Hum Free

(Designated by Suffix "HF")

The "HUM FREE" option eliminates the "AC hum" associated with AC operated solenoid valves. Enables valves to be used where an AC hum would not be acceptable and AC is the only power source available. IE: Hospitals, labs, schools (class rooms), homes, office environments etc. & when 24 vac is required for 40 series valves.

Leak/Dead Tight

(Normally Closed valves only)

(designated by Prefix "LT")

The Leak / Dead Tight Option is used where Low Pressure Tight Shutoff is required. This option offers ‘soft’ resilient seating or 'gapless' seal. Consult Factory for Max. Diff. Pressure and Valve Type availability.

Flanged Ends

(Designated by Suffix "F1" for 150 lb. or "F3" for 300 lb. Flanges)

150 lb. or 300 lb. Flanged ends available on all stainless steel solenoidvalves.

150 lb. Flanged ends available on bronze solenoid valves.

300 lb. Flanged ends for bronze solenoid valves available through our Clark-Cooper Division

Explosion Proof & Watertight Solenoids

(Designated by Prefix "F")

Are Explosion-proof and NEMA 4X, 7C & D, 9E, F & G suitable for use in hazardous locations requiring Class I, Div. 1 & 2, Groups C & D & Class II Groups E, F, and G equipment.

NEMA 4X

(Designated by Prefix "E" AND Suffix "ZP")

Are suitable for use in locations requiring a NEMA 4X designation. Zinc Plating replaces the standard paint used on the Coil housing (cup and base). The additional corrosion protection satisfies NEMA 4X requirements.

Internal construction, pressure ratings, power consumption, and external dimensions are the same as for standard solenoid valves.

Nickel Plating

(Designated by Suffix "NP")

Plating is 0.0005" Thick Meets Mil Spec. C26074

Website

Website